The Importance of Hydraulic Distributors in Auto and Motorcycle Parts

In today's fast-paced automotive industry, the need for efficient and reliable components cannot be overstated. Whether you're working on auto parts & supplies or motorcycle parts & supplies, having a dependable distributor hydraulic is crucial for both performance and safety. This article delves into the various aspects of hydraulic distributors and their significance in the world of machinery and vehicle maintenance.

What is a Hydraulic Distributor?

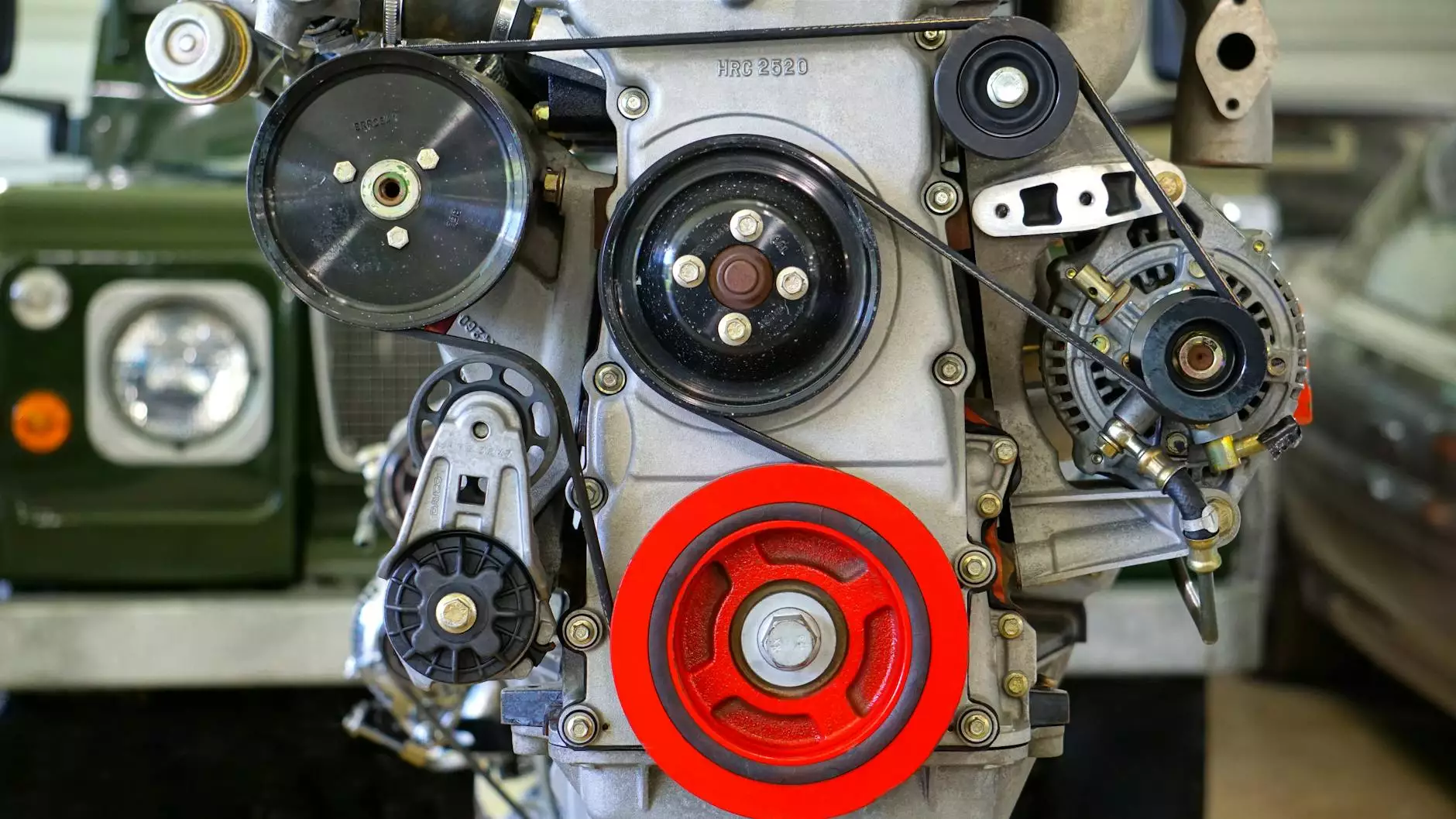

A distributor hydraulic is a critical component in hydraulic systems, responsible for directing hydraulic fluid to various parts of the machinery. It plays an integral role in ensuring that hydraulic components operate smoothly and efficiently. By controlling the flow and pressure of the hydraulic fluid, distributors facilitate precise movements necessary for different applications in both automotive and motorcycle systems.

Key Functions of Hydraulic Distributors

Hydraulic distributors serve several essential functions, including:

- Flow Control: They regulate the amount of hydraulic fluid flowing to various components, ensuring optimal performance.

- Pressure Regulation: By controlling pressure levels, hydraulic distributors help prevent system overloads and potential failures.

- Directional Control: They enable specific directional movements for cylinders and actuators, aiding in precise operations.

- Safety Mechanisms: Many distributors come with built-in safety features that help detect anomalies and prevent damage.

Types of Hydraulic Distributors

Understanding the different types of hydraulic distributors can help you choose the right one for your needs. Below are some common types:

1. Manual Hydraulic Distributors

These distributors require manual operation. They are often used in smaller machines where automated control is not necessary. Manual distributors are simple and cost-effective, making them a popular choice for basic automotive and motorcycle applications.

2. Electric Hydraulic Distributors

Electric hydraulic distributors are operated by electric signals, allowing for automated control. They are ideal for complex systems where precision and speed are crucial, such as in high-performance motorcycles and advanced automotive systems.

3. Proportional Hydraulic Distributors

These distributors offer variable flow control, allowing for precise adjustments based on system demands. Proportional distributors are commonly found in applications where fine-tuning of hydraulic pressure and flow is essential.

4. Sequence Hydraulic Distributors

Sequence distributors facilitate actions in a predetermined order. They are typically used in systems where multiple operations need to happen sequentially, such as robotic arms or automated assembly lines.

Benefits of Using Quality Hydraulic Distributors

Investing in high-quality hydraulic distributors is beneficial for several reasons:

- Enhanced Performance: Quality distributors improve the overall efficiency of the hydraulic system, leading to better performance of your vehicles.

- Increased Safety: Reliable components reduce the risk of failures and accidents, making your operations safer.

- Cost Savings: Investing in durable distributors minimizes the need for frequent replacements, ultimately saving you money.

- Improved Longevity: Quality hydraulic parts tend to have a longer lifespan, contributing to the overall longevity of your vehicles or machinery.

Choosing the Right Distributor Hydraulic

When selecting a hydraulic distributor, consider the following factors:

1. Compatibility

Ensure that the distributor is compatible with the existing hydraulic system of your vehicle or machinery. This includes checking the size, flow rate, and pressure ratings.

2. Quality Standards

Look for distributors that meet industry standards and are backed by reputable manufacturers. Quality certifications can provide assurance regarding the reliability of the product.

3. Application Needs

Consider the specific application. Are you working on a high-performance motorcycle or a standard vehicle? The demands of your project will dictate the type of distributor you need.

4. Budget

While it may be tempting to opt for the cheapest option available, investing in quality distributors often pays off in the long run. Consider your budget but prioritize reliability and performance.

Common Applications of Hydraulic Distributors

Hydraulic distributors are used across various applications in different industries. Some common applications include:

- Automotive Repairs: In auto shops, hydraulic distributors are vital for lifting and moving vehicles.

- Motorcycle Maintenance: Effective hydraulic systems enhance the operation of motorcycle brakes and clutches.

- Manufacturing: Hydraulic distributors play a significant role in factory automation, controlling machinery that requires precision.

- Aerospace: In aviation, hydraulic systems control various mechanisms, from landing gear to flight controls.

Hydraulic Distributor Maintenance Tips

To ensure the longevity and performance of your hydraulic distributors, follow these maintenance tips:

1. Regular Inspection

Conduct routine inspections of your hydraulic system to identify any signs of wear or damage on the distributor and associated components.

2. Keep it Clean

Ensure that the hydraulic fluid is clean and free from contaminants, as dirt and debris can cause significant damage to the distributor.

3. Monitor Fluid Levels

Check fluid levels regularly and top up as necessary to ensure optimal operation of the hydraulic system.

4. Replace Worn Parts

If you notice any deterioration in the distributor or related components, replace them promptly to prevent further issues.

Hydraulic Distributors: The Future of Automotive and Motorcycle Performance

As technology advances, the role of hydraulic distributors in automotive and motorcycle applications will continue to evolve. From improving energy efficiency to enhancing performance and safety, the innovations in hydraulic technology will shape the future of automotive engineering. By investing in quality hydraulic components from trusted distributor hydraulic suppliers like Shop Hydraulic America, you can ensure that your vehicles are equipped to meet the challenges of tomorrow.

Conclusion

In conclusion, understanding the vital role of hydraulic distributors in the auto and motorcycle industries is essential for anyone involved in vehicle maintenance or performance enhancement. From helping you select the right distributor to implementing maintenance tips, having proper knowledge will ensure that your hydraulic systems operate effectively. As you browse auto parts & supplies or motorcycle parts & supplies, keep in mind the importance of quality hydraulic distributors and their impact on vehicle performance and longevity.